BRM Announces Flexible Honing Tools For Chamfer Blending And Deburring; Flexible Hones Blend Chamfered Edges, Remove Burrs, And Improve Surface Finish For Machined Parts

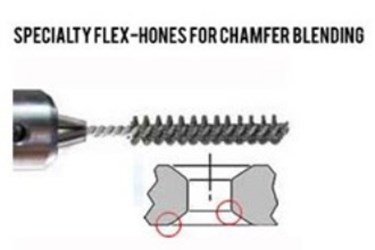

Brush Research Manufacturing (BRM), American-owned maker of flexible honing tools and a full line of industrial brushes, announces surface finishing solutions for burr removal and chamfered edges. Flex-Hone® tools for chamfer blending are designed to remove burrs, polish and radius chamfered surfaces, and improve overall surface quality for machined parts such as aerospace components.

Los Angeles, CA (PRWEB) - Brush Research Manufacturing (BRM), maker of flexible hones and industrial brushes, is announcing Flex-Hone® tools for chamfer-blending metal parts. Chamfering, the process of machining angled edges around the ends of cylindrical workpieces, offers a high degree of precision but can create secondary micro burrs that affect surface quality. If chamfered parts aren’t properly finished, part misalignment can occur.

Flex-Hone® tools eliminate time-consuming, hand-finishing operations and impart a polished, radiused surface to rotating parts such as aerospace components. Brush deburring also offers a flexible, cost-effective alternative to chamfering equipment that uses blades or cutting inserts and requires rigid setups. Brush tools do not create secondary micro burrs, nor do they affect part dimensions or concentricity. Instead, Flex-Hone® tools provide consistent, high-quality deburring and surface finishing.

Brush Deburring for Chamfered Edges

Flex-Hone® tools are built with a stiff metal stem, flexible nylon filaments, and ball-shaped abrasive globules. Versatile and easy-to-use, these cylinder hones mount in handheld power tools and existing production machinery. In addition to improving the internal surface finish of cylinders, flexible hones remove loose, torn, and folded metal. They can also deburr cross-drilled holes and slots.

BRM brush tools for chamfered edges are designed for use with cylinders ranging in size from 4 mm to 1” in diameter. In addition to polishing and radiusing the intersection of the chamfer and the flange face (outer corners), these deburring tools improve the surface finish of chamfered holes. Flexible hones can pass through thin sections, and are used to surface finish titanium, Inconel, super CVM, and nickel-based stainless steel alloys.

Choosing Flexible Hones for Chamfer Blending

The Flex-Hone® for chamfer blending is specified according to tool diameter, chamfer size, abrasive type, and grit selection. Tool diameter is determined by the nominal bore size in which the deburring tool will operate. Since the degree of oversize creates the Flex-Hone® tool’s soft cutting action, always order flexible hones in an oversize condition.

Chamfer size is given by range. Choose from Small, .005” to .015” (.12 mm - .38 mm) chamfer, per side; Medium, .015” to .030” (.38 mm - .76 mm) chamfer, per side; or Large, .030” to .050” (.76 mm – 1.27 mm chamfer, per side). With regard to abrasive type and grit selection, standard Flex-Hone® tools for chamfer blending comes in silicon carbide (SC) abrasive with 180 grit. Other grits and abrasive types are available by special order.

About Brush Research Manufacturing

Brush Research Manufacturing (BRM), makers of flexible honing tools and industrial brushes, is located in Los Angeles, California. For 55 years, BRM has been solving difficult finishing problems with brushing technology.BRM’s Flex-Hone® tool is the standard against which all other surface finishing solutions are compared.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2014/01/prweb11453689.htm