Parts Manufacturers Automate Deburring/Finishing To Speed Throughput

New abrasive technology delivers automated deburring and surface finishing in single operation

By automating deburring operations instead of handling it as part of a secondary process offline, CNC part and component manufacturers are reducing labor costs and speeding high-volume parts finishing.

Now, witha new advance in abrasive technology, machining center operators are now able toadd surface finishing simultaneously in the same operation to speed things even further.

For Eric Sun, Founder of Orange Vise Company, the unique combination of automated deburring and surfacing finishing allowed his company to eliminate several time consuming and laborious processes that had been slowing them down.

Orange Vise manufactures CNC machine vises and quick change fixturing components in Orange County, California, using a Mori Seiki NHX4000 high speed horizontal machining center.

As with most CNC machining centers, however, the process of deburring typically involved taking the part offline andhaving it addressed by hand using a variety of abrasive tools. Sun not only wanted to automate the process, but also eliminate a messy grinding processthe company was using to achieve a specific surface finish.

According to Sun, the company's CNC machine vises are constructed of different materials andsurface treatments. The body of the vise is made of cast iron with selectively hardened surfaces. The vise also comes with a variety of different sized with different heat treatments.

The hardened surfaces, which could measure as high as 50-60 on the Rockwell C Scale, required grinding because milling cutters would wear out too quickly. Out of necessity, Orange Vise would also grind the non-critical, unhardened surfaces to create a uniform appearance over the entire workpiece.

"This process involved removing, cleaning, and then repositioning parts several times to be able to grind each face. It was time intensive, particularly for the work that waspurely cosmetic," explains Sun.

It was at this time that Sun discovered anew abrasive tool from Brush Research Manufacturing, the abrasive technology company known for inventing the Flex-Hone Tool and turning it into a global brand.

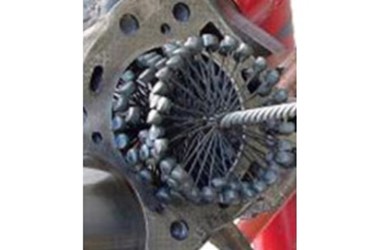

The company's new line of NamPower abrasive disc brushes are designed to allow CNC operators to automate the deburring process while delivering an ideal surface finish in the same operation.

"We started using the NamPower brushes for deburring, but quickly discovered they provided areally nice surface finish," says Sun.

Composed of flexible abrasive nylon filaments bonded to a fiber reinforced thermoplastic base, the NamPower abrasive disc brushes contain a unique combination of both ceramic and silicon carbide abrasive.

These abrasive filaments work like flexible files, conforming to part contours, wiping and filing across part edges and surfaces todeliver maximum burr removal rates along with an ideal surface finish. Other common uses are edge blending, part cleaning, and rust removal.

Although there are other abrasive nylon filament products that utilize siliconcarbide or ceramic, it is the combination of both in one tool that makes it unique. The ceramic abrasive is responsible for material removal, but tends to cut a bit coarse. The silicon carbide acts as a buffer to the cutting action. The result is deburring and finishing in a single operation.

The NamPower brushes work well with non-ferrous, cast iron, mild steel and ductile iron, stainless and alloy steels, titanium and high nickel alloys.

Sun's first decision was between the product's two available fill configurations: the Dot Style, for general purpose deburring and surface finishing and the Turbine Style, which has a higher density fill for surface finishing and the Turbine Style, which has a higher density fill for more aggressively deburring.

To achieve the smoothest finish possible and approximate the ground surfaces of the CNC vise, Sun says he selected the Dot style brush and intentionally reduced the spindle speed. He was immediately pleased with the results.

"The surface finish was good enoughthat we were actually blending it with our ground finishes," says Sun. "With large surfaces that required multiple passes, there were no visible blends. The whole thing looked like it was done in one pass."

"Needless to say, the brushes sped up the process quite a bit," adds Sun.

Orange Vise has found the Dot style NamPower brush to be flexible enough to conform to features of varying heights and could be used on other parts as well.

"We weren't expecting to use brushes so much, but we're finding more and more uses for them," says Sun. "We use the same brushes for aluminum, steel, cast iron and several other materials without having to swap them out very often."

One such application, and one of its primary purposes, is for edge blending.

According to Sun, Orange Vise utilizes a variety of deburring tools, includinga 45 degree chamfer. Although the tool doesn't typically leave a burr, when it begins to wear – even slightly – it can. Based on this potential, Orange Vise required an employee to inspect each part and handle any burrs by hand.

Now the company automatically deburrs chamfered holesand edges using the NamPower Brush.

In addition, Eric says Orange Vise does some engraving on the vice jaws, using a ball end mill. Although the engraving on the underside of the vice doesn't require deburring, Orange Vise wanted finer engraving on the top. For this, they used a 45 degree V-bit that created burrs. The options for removing the burrs were either to grind them out or to use the NamPower brush. Sun opted for the latter.

"Grinding would be so much more work. With the brushes it really doesn't take any extra effort at all. It adds maybe 30 seconds to the process," says Sun.

The NamPower brushes were developed with tool longevity in mind. Ceramic is an extremely durable material and there are reports of the brush lasting over 100,000 parts.

The brushes are essentially "self-sharpening" over their life, as well. Because of its linear construction, sharp new grains constantly come in contact with the work surface and wear off exposing fresh cutting particles. This provides consistent deburring action throughout the length of bristles.

"Weuse them just about every day and there's definitely no difference in performance from Day One until now," says Sun.

To eliminate filament smearing, improve surface finish and promote longer tool life, the discbrushes are also designed with a new tool holder that allows coolant to flow through its center for better lubricant dispersion. This permits the brushto run at greater cut depths while reducing heat generation. For more information, visit http://www.brushresearch.com/.

Source: Brush Research Manufacturing