CAD/CAM Provides Key Automation Of EDM Electrode Production, Part I

By Bill Blomquist

Programming Manager

American Mold & Engineering Inc.

This is Part 1 of a two-part article. Check back for the conclusion next week.

In recent years the emphasis in making tools for injection molding has been on machining, especially high-speed machining and, with it, a focus on automated generation of tool paths and at-the-machine programming. Taken together and tuned to the shop's operations and flow of work, this approach can yield quick results, straight-forward methods, and high-quality surface finishes.

A corollary to this machine-everything approach is eliminating as much electrical discharge machining (EDM) work as possible. The extra hours of setup time required for EDM and its extra programming load cut deeply into machining productivity. Even when EDM is well managed, most tool shop owners and managers see it as a major time-out.

But at American Mold & Engineering (AME; Fridley, MN) there is a great deal more to EDM than meets the eye. EDM rather than machining is our primary metal removal process for finishing. For us, electrode automation and EDM are by far the most cost-effective way of removing the last few thousandths of an inch of metal from a mold's cavity and core surfaces. Machining-oriented tool shops, in contrast, try to limit EDM strictly to "burning" fine details and sharp inside corners. And they constantly struggle to replace even those tasks with better cutting.

EDM's cost-effectiveness at AME is due to four factors:

- EDM's predictability, which is much greater than that of machining. Whether ganged together or produced as one large electrode, EDM can be left to run unattended on weekends. This is a major labor savings and it maximizes the work done by our five EDM machines.

- Machine tools capable of high-speed finishing work are two to five times more expensive than ordinary CNC machines suitable for roughing. More checking and maintenance are also required if the machines are to maintain their productivity.

- Machine tools capable of top-quality work may be ten times more costly than the EDMs. By comparison, an EDM is a relatively simple machine.

- Electrode production can be highly efficient thanks to specialized electrode milling machines. Purchasing one solved AME's biggest headache in using EDM as a production tool--an adequate supply of electrodes.

But the electrode mill created another problem. How could we generate enough toolpaths for electrodes to keep the machine busy and the EDM machines running nonstop?

Programming Bottleneck

Before we began using the electrode mill, a toolmaker or programmer could be a hero making one large electrode in a day including modeling, documentation, Q&A time and putting in the right mounting holes. (A large electrode can burn through an entire weekend.) Good programmers could make a small one in four hours.

But our methods were changing. We needed lots of small electrodes. Moreover, most "burns" need two electrodes; some needed three or more. Hundreds of electrode programs were needed every week. Since a typical job at AME requires 40 electrodes, each of which must be individually (and quickly) programmed, we had a near-perfect prescription for a production bottleneck.

Despite our best efforts, our new electrode mill was idle up to 70% of the time. Yet jobs were often stalled, sitting in an EDM machine's oil tank, waiting for more electrodes. Clearly there was potential for huge productivity gains and management insisted we find ways, preferably by automating the way toolpaths were generated for the electrode mill.

95% Time Savings

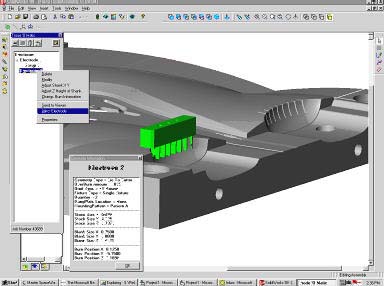

What AME developed is called Trode-O-Matic, a nearly automatic CAM programming system for electrodes. With the system, the average electrode is programmed in 20 min, a 95% time savings. Even very complex electrodes rarely take more than 35 min. Simple ones may take less than five.

Even better, most of this time is actually CPU processing time, an average of twice what the operator or programmer spends on each job. CPU time is far cheaper than labor and getting cheaper all the time.

With Trode-O-Matic, our OKK G4 electrode mill can now produce upwards of 200 electrodes in a week. The system is built on top of PowerMill CAM software from Delcam International Inc. (Windsor, ON, Canada). Trode-O-Matic went live at AME as a pilot project in late 1999 and was fully implemented in May.

A 50-person shop, AME produces a wide range of tooling. Tools built by AME produce parts ranging from plastic pallets to vacuum cleaner covers. This means Trode-O-Matic must accommodate toolmakers working to a broad scope of tolerances. In addition, many AME molds are large: 20 x 40 in. blocks are common, with a few as big as 80 x 160 in. To handle this, the automation must scale seamlessly between large and small jobs.

Large electrodes, for example, must be scaled up with efficient tool paths. If not, the cutter can raster back and forth over flats for days on end. By the time machining is done, one expects the steel to be rusted to the machine tool's bed. Trode-O-Matic and PowerMill eliminate this by face-milling flats at high speeds.

Success Stories

Trode-O-Matic initially proved its worth on a job for eight injection molds for disposable-camera components. We used an average of 140 electrodes a week for six weeks. Deadlines were tight and engineering changes came in almost daily.

Other noteworthy successes using the automated electrode system include:

- Molds for toner cartridges for a major supplier of office copiers. These intricate tools, with numerous boxes and bevels, must meet demanding statistical process control standards.

- Toolpaths and renderings for complete tools, not just cavity and core inserts to be dropped into mold bases, delivered in less than 48 hr. The customer, a major producer of housewares, tried to buy the process from us.

- Winning jobs from Japanese companies, even those with captive mold operations. American Mold regularly builds tooling for stereos and vacuum cleaners components.

The ironies in all this are obvious to all of us. We have used machining and leading-edge programming techniques to breathe new life into one of the oldest of toolmaking processes. The combination of the OKK electrode mill and Trode-O-Matic has sharply boosted the effectiveness of what was once tooling's mainstay production finishing process, die sinking.

The ironies have not escaped management. The automation techniques we developed for cutting graphite are being extended to the steel itself. This means some Trode-O-Matic methods have to be changed. Graphite is easier and quicker to cut than steel but far more fragile.

Part 2: Best Practices—And Redundant Ones

Delcam International, Inc., 3270 Electricity Drive Windsor, ON N8W 5J1 Canada. Phone (519) 974-8088; fax (519) 974-8170.