Company, students benefit from working on 'real world' problems

Madison Heights, MI clamp manufacturer De-Sta-Co Industries is helping engineering students gain valuable experience while streamlining operations at its Canton, MI facility.

Organized in conjunction with the University of Michigan (Ann Arbor), the work-study program allows students to earn course credits while applying problem-solving skills in a "real world" environment.

Most technical degree programs require completion of a senior project before –graduation, but not all students enjoy the advantages of corporate sponsorship. Programs such as the one at De-Sta-Co signal a shift away from theoretical problem solving to solutions that are applied on the shop floor. "Using students' research and development for practical production floor applications is the objective of most universities today," said Canton director of operations Dave Simon. "In the past, in many cases, research never left the university."

During the project's planning stages, De-Sta-Co management identified needs in the manufacturing environment where student assistance would provide a resource not immediately available within the company. Based on course studies and curriculum, Simon and John Cristiano, Adjunct Assistant Professor of Engineering, at the University of Michigan, developed assignments that would help resolve these challenges while giving students valuable hands-on exposure to the industry.

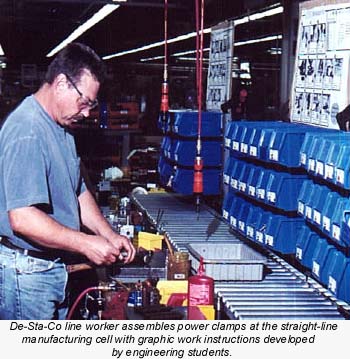

Two teams of students were asked to design a manufacturing cell layout and work instruction plan flexible enough to be used in the production of three types of power clamps. The first team developed a one-piece "straight-line cell" floor layout. Main objectives of the new manufacturing cell included better organization of the required material, increased flexibility, reduced changeover time, and optimized productivity. Special attention was paid to workspace ergonomics for enhanced ease of use.

The second group designed a "visual factory" to facilitate quicker, more economical training and better communication on the shop floor. Key features of the system include easy-to-understand graphic work instructions and inventory books, and improved material handling and inventory organization systems.

Simon believes programs such as De-Sta-Co's give students a significantly better chance at finding jobs after graduation. "Students can now demonstrate working knowledge of industry applications [to] a potential employer." And, he adds, there is also a greater possibility that students will be considered for hire by the sponsoring company.

De-Sta-Co Industries, 31791 Sherman Drive, Madison Heights, MI 49071 USA. Phone (248) 397-6700; fax (248) 397-6734.

Edited by Jim Destefani

Managing Editor, ToolingOnline.com