Cutting Tools Key to High-Speed Mold and Die Machining

By Derek Giles

Manager, Rotating Tool Products

Carboloy Inc.

Today, thousands of machine shops in the U.S. are involved in machining hard tooling used to form, mold, or stamp a seemingly limitless range of consumer and industrial products.

To meet customer expectations and competitive pressures for higher tool quality, shorter turnaround times, and lower cost, many die and mold shops are upgrading their processes with capabilities for high-speed finishing operations. This results in machined surface finishes that are fine enough to substantially reduce or even eliminate hand polishing or other manual finishing procedures at the bench. Such secondary operations typically account for as much as 25% to 30% of total manufacturing time.

Technical Advances

High-speed finishing of dies and molds is made possible in part by the spindle-speed capabilities of today's machine tools. Whether the equipment used is a small vertical machining center or a large-bed horizontal CNC, spindle speeds upwards of 10,000 rpm can now be routinely obtained. Such speeds are easily accommodated by current secure toolholding methods, which may incorporate precision collet chucks, shrink-fit, mechanical, or hydraulic chucks.

An equally important aspect of high-speed finishing of molds and dies is high tool feedrates. In combination with the higher spindle speeds, the high feedrates produce excellent machining results at the shallow depths of cut and small stepovers (cusp heights) needed to achieve fine surface finishes.

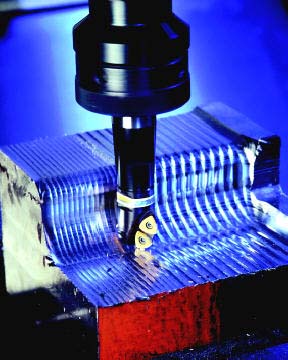

As for the cutting tools themselves, Carboloy has found that in order to be successfully applied in high-speed milling of dies and molds hardened to 55 Rc, they need to be able to routinely run at a feed of 300 ipm. Good quality, conventional PVD-coated micrograin carbide inserts should be able to produce a 25-microinch finish at this feedrate, with axial and radial depths of cut on the order of 0.002 in. and 0.010 in., respectively. Tool design innovations linked with new machining strategies, such as the use of a 120-deg ballnose endmill for high-speed finishing of the vertical walls of dies and molds in place of the conventionally employed 90º ballnose endmill, also can yield significant benefits in die/mold machining productivity.

Along with advances in cutting tools, which is the continuing focus of Carboloy's research efforts, a number of other developments are supporting new levels of productivity in die & mold machining. One example is CNC machining centers in horizontal configurations, which are rapidly replacing traditional vertical CNCs in both the die & mold and aerospace industries. A major benefit of the horizontals is that they allow a natural fall-away of chips, greatly reducing chip recutting in closed-cavity operations.

Another development has permitted improved performance of ballnose endmills. This is a setup technique first introduced in Europe for countering the rubbing associated with ballnose cutters because of the zero cutting speed at their center. To eliminate the rubbing and consequent dull finishes and rapid insert wear, a growing practice is to tilt the machine tool's spindle 30 deg, which moves the cutting action from the nose of the tool to an effective cutting diameter.

In still another development, near-net-shape castings are now widely used in Europe for producing dies and molds, eliminating rough machining requirements. Although competitive pressures are sure to eventually extend this technology worldwide, mold and die shops in North America continue almost exclusively to machine their tools from solid. For now, that lends even greater importance to innovations in roughing tools, such as the helical flute, ballnose and button cutters, that can remove hardened metal at significantly higher rates.

More Points to Ponder

For high-speed applications in die and mold machining, attention must also be given to some further considerations. It must be remembered, for example, that high spindle speeds allow a dramatic increase in feedrates, as well as cutting speeds. This makes it possible to use smaller tool diameters for both roughing and finishing, permitting closer approximations to finished net shape while at the same time achieving equal or better productivity rates. Tool balance, based on selecting the right holder design, is also important for preventing excessive vibration and consequent tool runout that can adversely affect tool life, surface finish, dimensional accuracy, and even the life of the spindle.

Still another consideration is the machine control. Effective machining of the complex sculpted surfaces of dies and molds at very high speeds and feeds requires a CNC with "look ahead" functionality--the ability to scan the machine's upcoming moves some 100 to 120 program blocks ahead of the movement being performed, so that the control can optimize feedrates for toolpath and geometry changes. This allows the machine to maintain both speed and accuracy while machining complex surfaces, with the possible exception of those in deep cavities and with complex shapes.

Looking Ahead

What does the future hold? One sure thing is even higher cutting speeds. Several machining centers with spindle speeds between 60,000 and 80,000 rpm will soon be available, driven by motors rated at upwards of 100 hp. (A rule of thumb is that at least 1 hp must be available for every 1,000 rpm of spindle speed.)

Needless to say, these machines will place new demands on tooling in many areas, including safety, which is often overlooked. Currently, Carboloy's Minimaster line of ballnose endmills, for example, can safely run at cutting speeds up to about 12,000 sfm, depending on the cutter diameter.

This is a standard, however, that may not be matched by many other small-diameter cutters, particularly those with center-lock screw or wedge designs for insert retention. It is important to be aware that, though your machine may be capable of high-speed machining, you can't automatically assume that your tools will be, too.

Carboloy, A Seco Tools Company, 11777 E. Eight Mile Rd., Warren, MI 48089. Phone (800) 832-8326; fax (810) 497-5627.