High-density workholding maximizes spindle utilization

Keeping the spindle turning in CNC machining centers is said to be the key to success these days.

That is certainly the case at JEM Technical Marketing (Long Lake, MN), where success means keeping spindles turning 24 hours a day.

The company's secret is found in enhancements to its high-density workholding, which allows JEM to double the parts it holds in its Kurt Cluster Tower setups. The result is that JEM is able to keep its new machining center turning unattended for an extra 7-hour shift in every 24-hour workday.

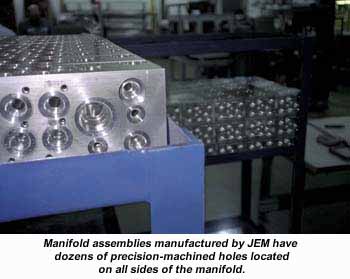

JEM manufactures a broad line of custom manifold assemblies used in all types of fluid power applications such as off-highway vehicles, tractors and road graders. These manifolds are made from 6061 aluminum and are finish machined in a wide range of sizes and with numerous SAE ports, valve cavities and threaded holes, some with precision features designed to handle various fluid power components.

Manifold assemblies are manufactured for large OEM applications, but are also available for limited application use. Part runs vary from just one to more than 3,000 units with the required machining accuracies ranging from 0.0005- to 0.001-in. To achieve real production efficiency with this diverse product mix, JEM Technical decided something had to be done with its workholding to maximize productivity.

The solution chosen was using high-density Kurt workholding with serrated interlocking of modular components. "Our precision manifold machining process is all about high density," says Peter Tackes, manufacturing manager for JEM. "We've taken a two-station per face setup on the Kurt CarvLock cluster towers and gone to four. That doubles the capacity of each tower setup and allows our operators to set up enough parts offline to run unattended through the night."

JEM Technical operates a new Mazak FH 4800 Palletech system, which features spindle speeds to 12,000 rpm with a tool change time of 3.0 seconds (chip to chip). The machine is used for a combination of milling, drilling, tapping and boring operations. The system has a rapid traverse rate up to 1,968 ipm in all axes and up to 30-hp in the spindle. Equipped with a 120-tool ATC, the machine has X-Y-Z travels of 22- × 24-× × 22-in.

JEM utilizes Kurt CarvLock cluster towers on the system, and just recently started using a new model with mating serrated mounting surfaces. From a distance, it appears like those towers are the ones that have been around for a number of years. But if you look more closely, you'll see a new feature—serrated mounting surfaces.

Matching grooves and ridges on the mating surfaces of the fixture blocks clamped to the mounting plates are precisely shaped and spaced so that the match between the surfaces is very nearly perfect. When these opposing grooves and ridges come together, they interlock, forming a rigid, firm, level, and highly repeatable interface. Matching the grooves and ridges naturally and automatically aligns the surfaces, making subsequent re-clampings highly repeatable. JEM Technical sets up their SeraLock cluster towers with three and sometimes four workholding stations per facing, depending on part size.

The system incorporates Kurt MoveLocks, which are simple, two-piece vises that provide independent mounting of stationary and moveable elements in the setup. What's different in this setup are the intermediate modules, or the combination spacer/lockdown devices, which are positioned between each of the workholding stations. They have the functions of aligning, holding and locking down the parts to be machined.

Key to the system is in the accuracy of the serrations, both in form and in spacing. A firm, level, and repeatable interface cannot be achieved if the serrations on both the subplate and clamping element are not a perfect match. The spacing, or pitch, of the serrations allows the use of a variety of economical, short-stroke clamping elements. The moveable and stationary components of the clamp can be located relative to one another on the subplate so that the needed stroke of the moveable component need be little more than the pitch of the serration. In the SeraLock system, a sixteen pitch (sixteen serrations per inch) pattern is utilized. Thus, the stroke of the clamping elements need not exceed 0.062-in. unless otherwise dictated by workpiece configuration.

Different clamping elements promote workholding flexibility. Repeat setups are easy, because the SeraLock serrations take care of location and alignment of clamping elements. And because of the versatility inherent in the system, setups ranging from extremely high-density loads of small parts to single station configurations for very large workpieces can be accommodated on the same workholding surface.

Tackes says that the system has helped triple output in its nine-man machining department without adding more help. "We keep the machines running with operator attention and setup through the end of the second shift. Toward the end of that shift, the operator carefully checks the first run of parts. If all check out, and they usually do because we've done our setup homework, they'll be machined to spec without operator attention during the 11 to 6 shift."

Kurt Manufacturing, Industrial Products Division, 1325 Quincy Street NE, Minneapolis, MN 55413 USA. Tel: 800-328-2565. Fax: 612-623-3902.

JEM Technical Marketing, 2250 Daniels Street, Long Lake, MN 55356 USA. Tel: 612-473-5012.

Edited by Jim Destafani

Managing Editor, Tooling Online