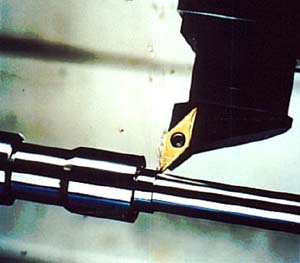

Improved Turning Grade Guaranteed to Increase Speed

Ultraspeed GC4015 grade steel turning tools permit a guaranteed speed increase of at least 20% over the existing grade, according to developer Sandvik Coromant (Fairlawn, NJ).

Re-engineering of the tool's substrate and coating increase the new grade's productivity for steel turning jobs. The same technology has also been incorporated into grades GC4025 and GC4035. Together, the tools cover the full range of toughness and wear-resistance features needed for optimizing performance in steel turning applications.

The substrate now applies an advanced gradient sintering process to vary the tungsten carbide/cobalt composition along the tool's periphery. The flank is enriched with cobalt to provide toughness, assuring better edge security under demanding conditions. The nose area is enriched with tungsten carbide to impart hardness, resist wear, and minimize plastic deformation.

The patented coating process deposits a thick layer of aluminum oxide with columnar crystals oriented perpendicular to the surface and the substrate. The columnar orientation presents the most wear-resistant surface to the cutting face. It also provides a path for crack formation and propagation in the coating, leaving the basic insert intact.

The combination of gradient sintering and coating crystal orientation creates inserts that can withstand higher cutting forces and temperatures without failing, according to Sandvik. That most often translates to an increase in cutting speed of 20% or more, because increasing cutting speed improves process economics by a factor 20-40 times greater than extending edge life at the same speed, the company says.

Greater resistance to heat also reduces the need for coolant, and Sandvik says the new inserts work equally well wet or dry. With elimination of coolant, metalcutting operations reduce or eliminate coolant cost, part washing, housekeeping and environmental concerns.

Sandvik Coromant Company, 1702 Nevins Road, Fair Lawn, NJ 07401. Phone (201) 794-5000; fax (201) 794-5217.