Modular Tooling System Meets Job Shop Requirements

Custom Tools From Standard Components

Ultimate Precision Inc. (Madison Heights, MI) provides precision machining services for customers in the automotive and other industries. Quick response is at the heart of Ultimate's business, so it relies heavily on agile production equipment, including CNC machining centers and flexible tooling.

A quantity of cast-iron hydraulic pump housings machined on a production off-load basis for a builder of special machine tools offers a case in point. In producing the 10 in. x 8 in. parts from raw castings, the company had to finish machine two ID bores and one OD surface ranging from 3.3 to 5 in. diam. Dimensional and surface finish tolerances were tight. The cuts, and several other finishing operations, were performed on a 40-hp Niigata HMC.

Ultimate couldn't use standard dedicated tooling for either the 3.3-in. diam finish-boring cut, which required an 8-in. tool overhang, or the 5-in. diam OD cut, which had to be performed using a finish-boring tool that required a special setup. At the same time, custom-made special tooling was ruled out for these cuts, because of the fast turnaround required for producing the parts.

The solution was to create special tooling from components available in the Graflex modular tooling system, which is manufactured by EPB SA of France and marketed exclusively in North America by Carboloy Inc. (Detroit, MI). The system consists of an array of standard interchangeable tooling components that can be quickly and easily assembled for boring, milling, drilling, tapping or turning applications. The system can meet special tooling requirements, as well as provide broad versatility in standard tool applications. Graflex tools also have adjustable boring heads.

Flex-Free Overhang

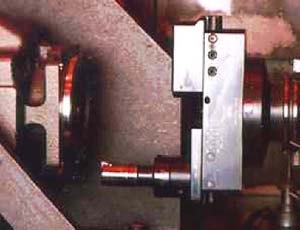

The long reach capabilities of the tooling were amply demonstrated in finish machining a 3.2635-in. diam bore (+/- 0.0005 in. tolerance) in the hydraulic pump housings that accepts the bearing diameter for the pump drive shaft. The operation required an 8-in. tool extension to reach the face of the bore. To achieve the required reach, two 2.95 in.-long tool extensions were coupled with a radial-type balanceable single-point finish boring head with an adjustable diameter of 2.52 to 3.39 in.

Overall concentricity of the extended-reach tool assembly is maintained by a patented connection, which ensures tool rigidity in three ways. First, any two components in the assembly are tightly connected by two ball screws placed 120 deg apart. A guiding tenon, or key, prevents misalignment. Second, face contact pressure obtained by screw tightening provides absolute rigidity throughout the system. And third, cutting forces during machining further tighten the connection between pairs of components. With this three-way connection system, the assembled tool maintains precise concentricity in use, holding a flex-free 0.005 in. true-position tolerance even at extended reach.

Despite the 8 in. tool overhang, the system consistently met dimensional and surface finish requirements in finish-machining the main-shaft bearing diameter bore of the pump housings. Average machining time for the cut, taken at a surface speed of 342 sfpm and a feed of 2.5 ipm, was 15 sec.

Precision OD Cut

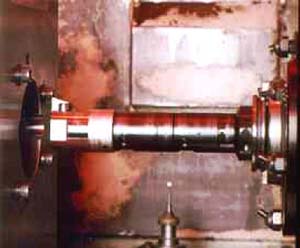

Capabilities of the Graflex system for creative tool assembly were fully exploited in setting up the OD finishing operation on the 5-in. diam, roughly ½-in. long surface used to pilot a mating component of the pump housing that holds the drive assembly. Such operations are normally performed on a lathe, but Ultimate wanted to do the finishing on a machining center to save time and cost.

The company combined a small-diameter radial-adjustable single-point boring head (1.181- to 1.575-in. diam capacity) with six tooling components: a 1.57-in. tool extension, an adapter to connect the boring head and extension to a spindle base plate, the spindle base plate, a second adapter to connect the spindle base plate to the spindle, and two counterweights to balance the tool rotation. to perform the OD operation with what was essentially a boring tool assembly, the fine-adjustable boring head had to be inverted to take an OD cut and the spindle motion reversed.

Despite the unusual tool configuration and machining technique, the operation consistently met requirements for an OD size tolerance of 4.9980 to 4.9999 in. with surface finish of 63 m. Average machining time for the operation, run at a surface speed of 1212 sfpm, a feed of 4.0 ipm and a 0.020-in. depth of cut, was 8 sec.

Graflex modular tooling also was used for a third bore. Average cycle time for complete finish machining of the pump housings, including the three Graflex cuts and several other operations, was less than 6 minutes.

All the operations performed with modular boring tools were run with 80-deg diamond inserts using Carboloy's TP100 core turning grade for high-speed and medium machining of cast irons and steels. The grade was recently reintroduced with a new 3-m thick multilayer TiN top coating. Operators indexed the inserts only at normal shift breaks every 11-1/2 hr. No incidence of excessive wear or insert fracture was detected over the production cycle.

Carboloy, A Seco Tools Company, 11777 E. Eight Mile Rd., Warren, MI 48089. Phone (810) 497-5000.