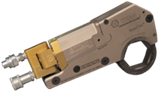

Titan Introduces Super Thin Hydraulic Torque Wrench For BOP Applications

Titan Technologies, a leading manufacturer of industrial bolting tools, announces their new line of hydraulic torque wrenches for blowout preventer service in limited space applications.

Houston, Texas (PRWEB) -In response to e need for durable blowout preventer (BOP) tools for the oil and gas industries, that can also perform well in tight spaces, Houston-based Titan Technologies has developed a new line of thin hydraulic torque wrenches designed for use in these demanding, limited space applications.

The result of thousands of man-hours of research and development, the Titan SuperThin™ Series is the only line of BOP hydraulic torque wrenches on the market specifically built to deliver accurate and repeatable torque in tight, narrow spaces. Using a Titan standard low profile power head cylinder, the SuperThin™ Series allows continuous ratcheting in limited space applications, eliminating the need for the time-consuming and inaccurate bolting methods used in the past.

Blowout preventers are critical to the safety of oil and gas workers, their equipment, and the environment. As a fail-safe device, they rely on proper construction and regular maintenance performed with tools made for the job. This thinner, stronger hydraulic torque wrench designed and manufactured by Titan answers the challenges presented by limited accessibility on BOPs.

With the smallest radial footprint of any hydraulic torque wrench in the industry, Titan Technologies expects that the SuperThin™ Series BOP tools will work with over 90% of blowout preventers manufactured today. Common applications include wellheads, gate valves, stand pipe valves, choke manifold valves and many types of BOPs.

This new line of hydraulic torque wrenches is designed to meet the requirements of BOP work for both manufacturing and use in the field to break out and repair. An extreme low profile link design uses a concentric strap to provide better accessibility in tight spaces, long-lasting performance, power and accuracy.

Features specific to the SuperThin™ Series include:

- Smallest link radius on the market

- Can be used with Titan LP power head cylinders

- Multi-Axis Swivel Assembly

- Comprehensive warranty

- Torque ranges from 390 ft. lbs of torque to 3900 ft. lbs. of torque

- Available in a wide range of hex nut sizes

The SuperThin™ BOP tools are made from aircraft-grade alloys for durability and strength, and are expected to deliver a good return on investment in the form of long-lasting performance, efficiency of operation, lower cost of ownership and increased safety. These tools are manufactured by Titan in the USA.

Mass production has begun, with inventory ready to be shipped to end users worldwide. Local Titan representatives are now offering free, no-obligation in-house demonstrations for anyone in need of cost-effective BOP tools that can handle the challenges of limited radial and axial space.

About Titan Technologies

Titan Technologies is a leading manufacturer of hydraulic torque wrenches, pneumatic and electric torque wrenches, hydraulic tensioning and other high-end bolting solutions. Titan has its headquarters in Houston, Texas with offices worldwide and distribution in over forty countries.

Source: PRWeb

View original release here: http://www.prweb.com/releases/hydraulic-torque-wrenches/titan-st-series-intro/prweb9640407.htm